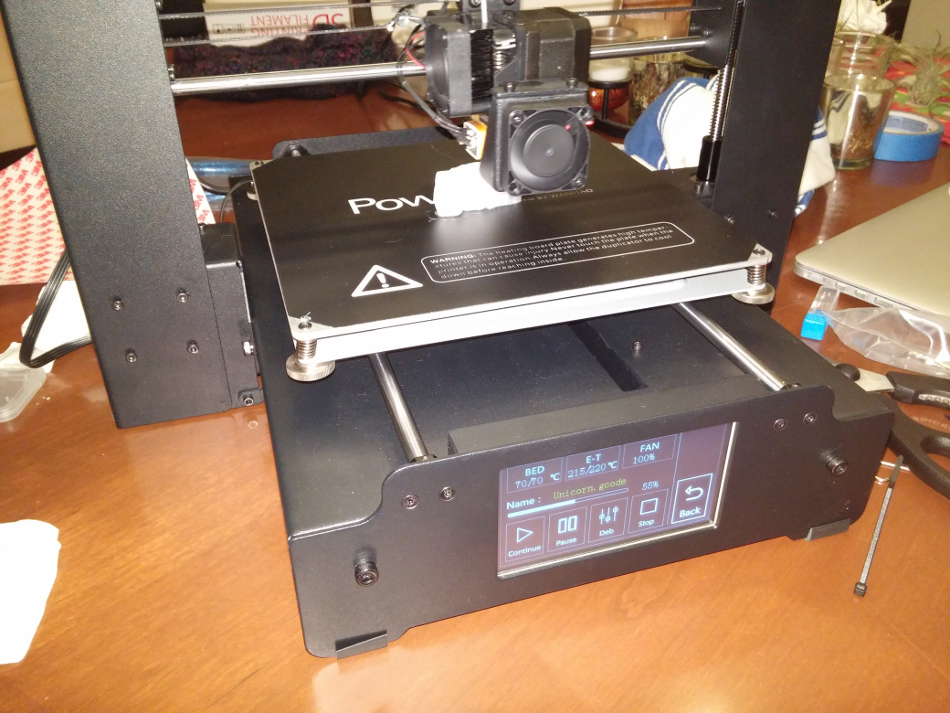

I haven’t been doing much around the shop recently. The weather hasn’t been nice enough to fire up the foundry, and for the past couple months I haven’t had a side project going. However, I recently had the opportunity to get a good deal on a 3D printer. It’s a clone of the Wanhao Duplicator i3 plus, co-branded with PowerSpec. The unicorn is a test print in PLA with the default configuration and settings. It turned out pretty well, with a decent surface finish, though there’s some globbing and warping on the ears and horn.

I’ve been playing around with the Gingery Foundry and I’ve discovered that lost foam casting is dramatically easier than trying to make split forms in sand. With green sand cope-and-drag casting you have to make the pattern in wood, ram up half the mold, flip it over without spilling sand everywhere, ram up the other half the mold, lift off the cope - again without spilling sand everywhere, gingerly take out the pattern, line your cope and drag up properly, and then pour your melt.

With lost foam casting you basically just have to make the pattern in foam and bury it in sand. It doesn’t even need to be special sand. Regular old play sand works pretty well. If you want a better surface finish, you can coat the pattern in something like drywall mud before you bury it. Plus you can cast a much wider variety of shapes and not have to worry about parting plane geometry. It’s just all around easier.

Since we’ve moved into our house, there has been a bare patch in the back yard from the previous owners. It looks like it was intended to be a garden, but as far as we can tell, nothing has ever actually been planted in it. We decided we wanted to level it out and turn it into a more functional (and aesthetically pleasing) garden space.

We figured out where the sprinkler heads were (and how they were connected underground) so we wouldn’t inadvertently dig through a sprinkler line. The heads were located in such a way that we could cut behind them and fill in front of them to make a terrace without changing the height of the sprinklers themselves. After we had planned out where we wanted our terraces, the digging was the hardest part. Laying the bricks and backfilling went pretty quickly after the digging was done. The terracing is definitely an improvement, but the soil is basically just clay so there’s a lot of work still to do before it becomes a decent garden.

This post is part of a series on making and using the Gingery Foundry.

Over the previous posts, I’ve made all the parts and accessories required to run a Gingery Foundry but had yet to actually cast any metal. Time for a test run!

My first test with the new foundry was a categoric failure. Even running at full blast, the furnace simply wasn’t getting hot enough to melt aluminum. It seemed like it was getting plenty of air, and containing the heat well (the outside of the furnace body stayed relatively cool), so I figured it was a problem with my fuel. I was trying to use “long burning” charcoal briquettes, which presumably had some additive in them to try to keep your grill from getting too hot. I picked up some lump hardwood charcoal at the store and tried again a couple weeks later.

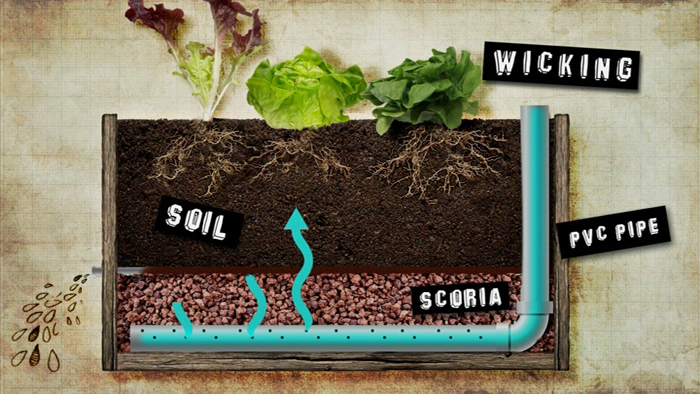

In a digression from the recent Gingery projects, my wife and I have been wanting to do some gardening. Trying to detangle the HOA regulations about “major landscaping changes” was taking a lot of time, so we decided to put together a little planter garden on the back porch. Since we’re nerds, and generally busy nerds, we decided to make self-watering planters.