This post is part of a series on making and using the Gingery Foundry.

One of the most critical elements of the solid fuel foundry is the air supply. A constant blast of air is what lets the furnace get hot enough to melt metal. Gingery recommends using a bonnet hair dryer to feed the furnace blast, but since I don’t have one I’ll be using the the blower output from a shop vac.

Unfortunately, using a shop vac for a furnace this size is tremendously overpowered. Running the air at full blast for any length of time would melt my furnace down into slag and glass. I need some way to control how much air is actually being directed into the furnace.

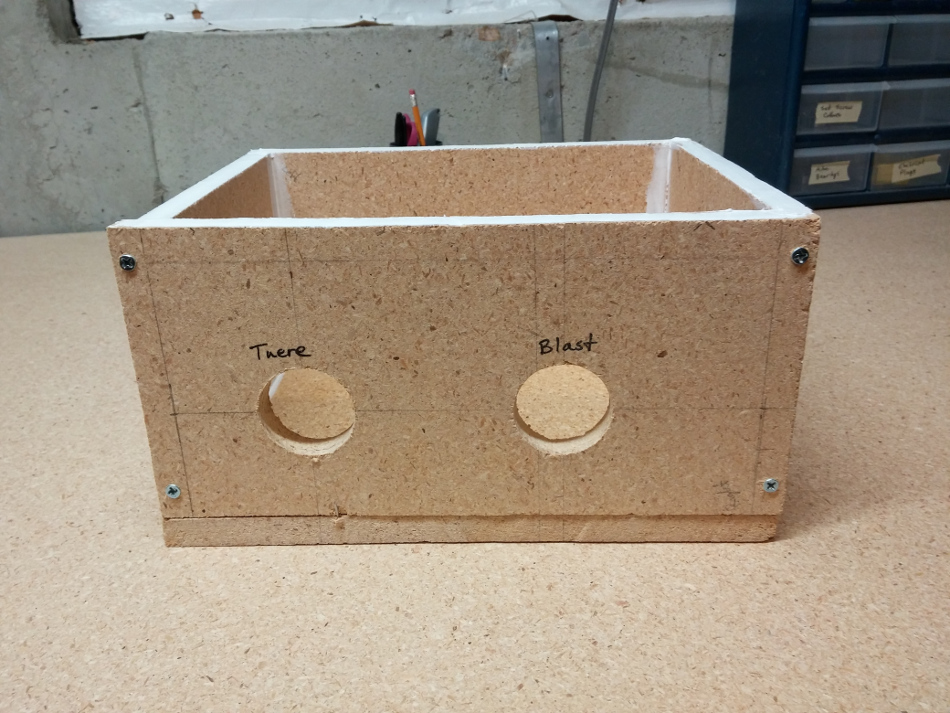

Enter the blast control box. The idea is to convert the head pressure from the shop vac into static pressure in a sealed wooden box. Using a swinging box top, the amount of air escaping from the box, and thus the box static pressure, can be varied. The flow of air through the blast outlet (and into the furnace) will vary in direct proportion to this static pressure.

I made the box out of ⅝” particleboard (left over from when I made the work benches). The precise dimensions don’t particularly matter. Two 1 ¾” holes are cut on one side of the box (using a hole saw). These are sized to fit a shop vac tube and a piece of 1 ¼” steel pipe.

Once I had it made, I gave it a coat of varnish and sealed up the inside cracks to make it a little more air-tight. I then attached and hinged the top of the box with a single nail through the corner. When the top of the box is swung open, the pressure in the control box (and the air blast) is reduced. As the box top is swung closed, more and more air is trapped in the box and forced out the pipe to the furnace.