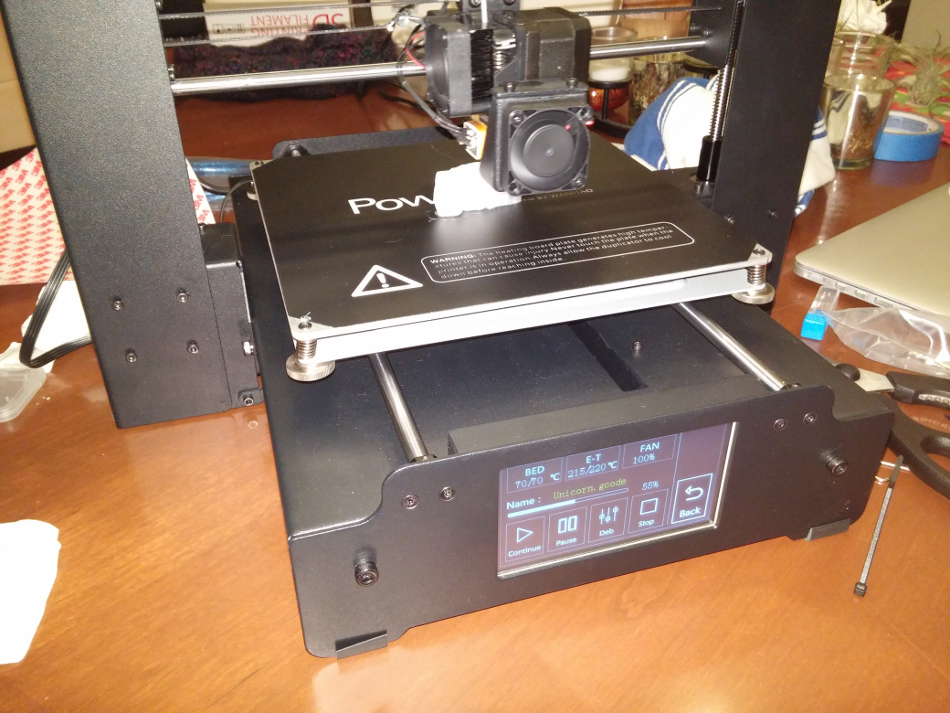

I haven’t been doing much around the shop recently. The weather hasn’t been nice enough to fire up the foundry, and for the past couple months I haven’t had a side project going. However, I recently had the opportunity to get a good deal on a 3D printer. It’s a clone of the Wanhao Duplicator i3 plus, co-branded with PowerSpec. The unicorn is a test print in PLA with the default configuration and settings. It turned out pretty well, with a decent surface finish, though there’s some globbing and warping on the ears and horn.

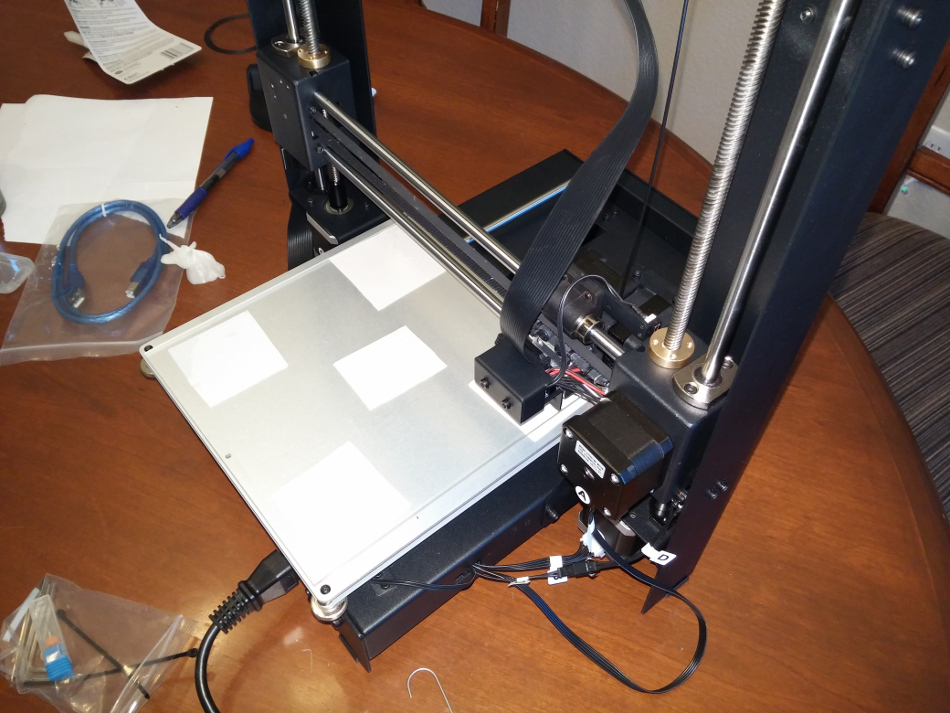

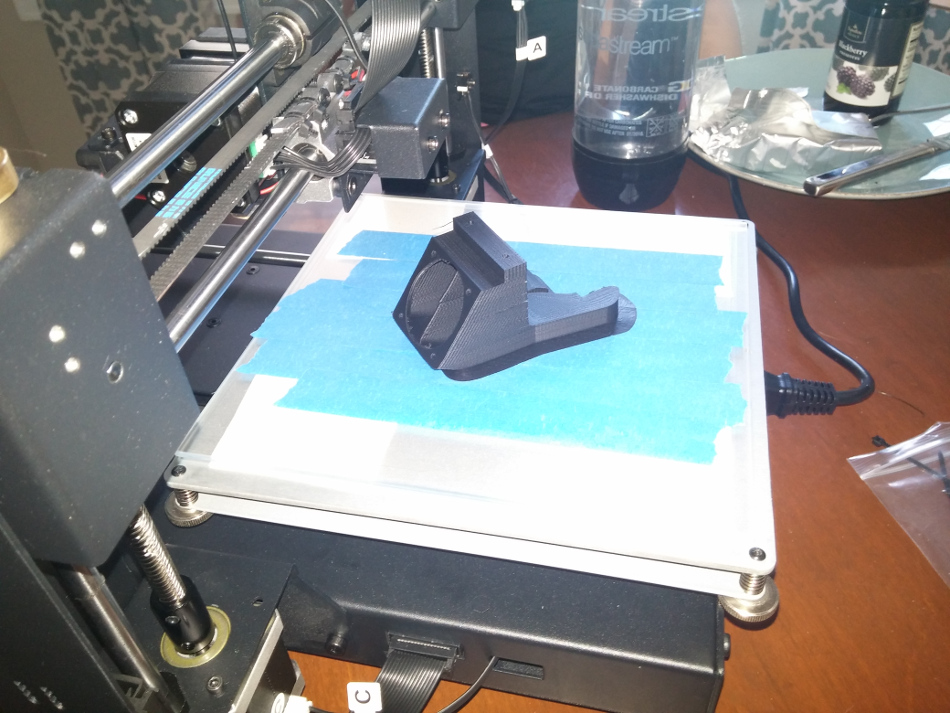

Naturally, the first thing to do with a 3D printer is to make improvements to the 3D printer. I added a glass bed to it first. This is just a piece of tempered glass cut to the appropriate size, with some thermal pads underneath it to conduct the heat up from the original aluminum bed. This stays true flat as the bed heats up (while the metal underneath deforms slightly), so it’s easier to level. I’ve had some problems with prints not sticking to the glass. Extra-strength hairspray is the most common solution, but I couldn’t get that working. I’ve had to use painters tape with larger prints to keep them from coming loose during the print.

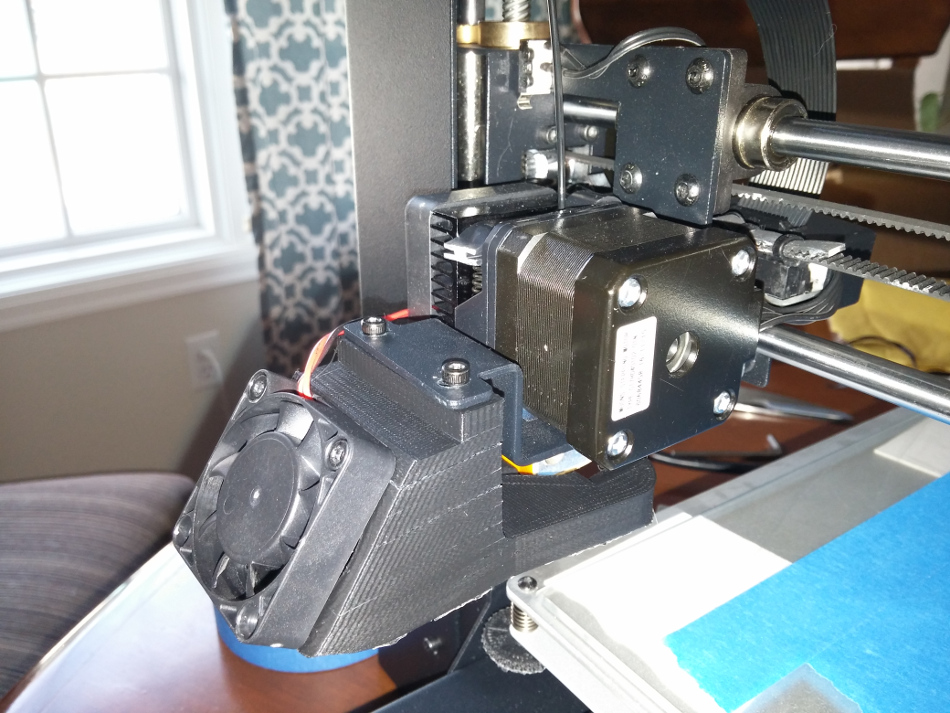

Next up was a better fan hood. The stock hood just blows air in the vague direction of the extruder head, I printed out a custom hood in ABS to direct air around the head better. Turned out with a very nice surface finish, though you can see some cracking (patched with superglue) in the second picture.

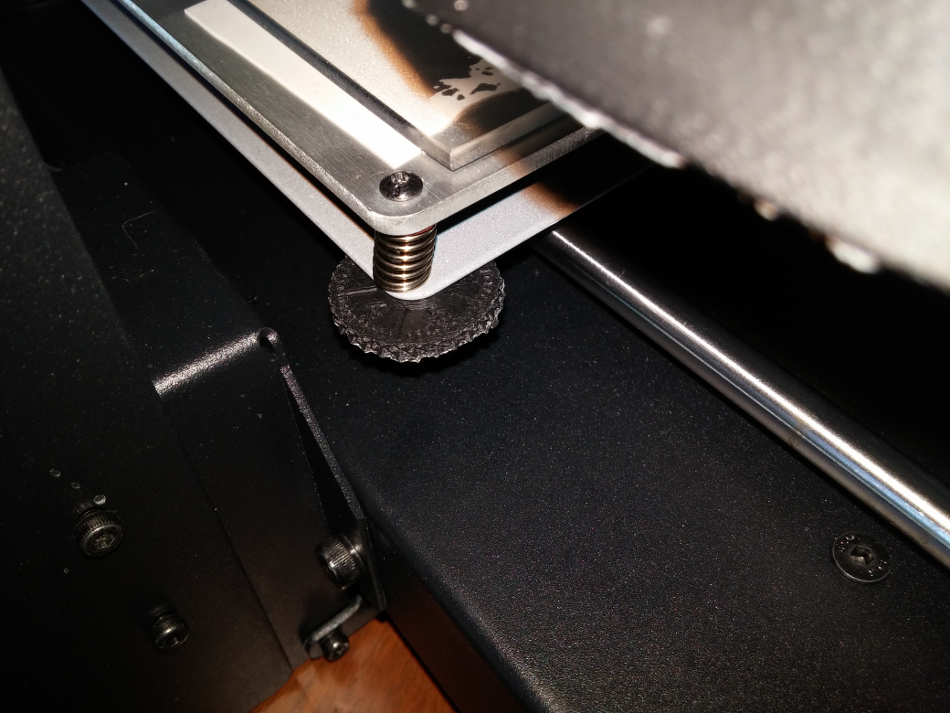

The final mod I made was to print some custom thumbwheels for the bed leveling screws. These actually have numbers and increments marked on the wheel, allowing for more precise adjustment during bed leveling.